10 patents (7 invention patents included), the only type of elemental analyzers with auto combustion crucible replacing device.

High Precision:

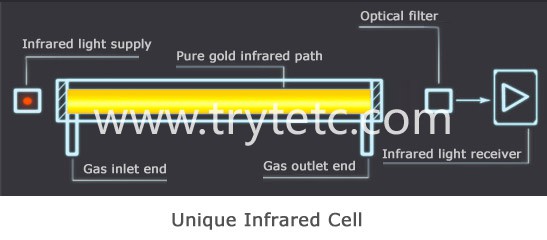

ŌæĀ Self developed ultra-low drift infrared cell (Patent No. ZL200920318535.8) adopts the high-performance infrared light, electronic components, optical glass as well as infrared light receiving device. The drift of infrared cell is greatly reduced (calibrate every 3 hours or even longer time).

ŌæĪ Self developedultra low temperature drift TCD and thermalstatic diffusion type TCD ensure the stability of TC reference line (TR-CHN435 elemental analyzeronly).

High automation and test efficiency’╝Ü

ŌæĀ Autoloader with 34 position, automatic sample introduction and test.

ŌæĪ Analysis time of elemental analyzer for a single sample is less than 5 minutes, new samples can be added or replaced during the analysis process.

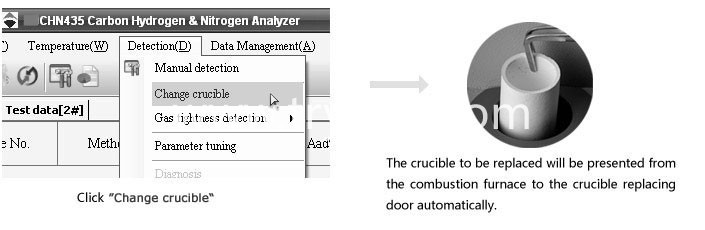

Ōæó Combustion crucible can be replaced automatically (Patent No.: ZL200710303473.9), no disassembling, no cooling, no damage to the furnace and combustion tubes. Operator is away from high temperature and danger.

Humanization Design and convenient operation:

ŌæĀ Easy and convenient for gas leakage check, operators only need to click on the software.

ŌæĪ Convenient to replace the Furnace Reagent. With separate design of combustion furnace and reagent furnace, reagent can be easily and safely replaced with the minimal amount of effort.

Ōæó Floor standing design with superior wheels and wheel locking device for all elemental analyzers, itŌĆÖs convenient to shift the instrument from place to place.

ŌæŻ Enlarged combustion crucible for elemental analyzer can greatly reduce the frequency of crucible changing.

Low operation cost:

ŌæĀ Helium consumption is only 0.7L/min for each test, which reduces the gas consumption greatly. Nitrogen analysis part can be stopped optionally if necessary.’╝łSDCHN435 elemental analyzer only’╝ē

ŌæĪ Oxygen with purity of 99.5% can meet the test requirement of all elemental analyzers.

Intelligent Control’╝Ü

ŌæĀEasy-to-use Windows-based softwarefor allelemental analyzers, easy data handling, real time data can be transmitted by internal network.

ŌæĪ With CAN bus interface, several elemental analyzers can be controlled by a single PC without mutual influence

Ōæó It can be connected with balance and network by standard interface RS232.

Critical Innovation:

Unique automated design makes the operation easy.

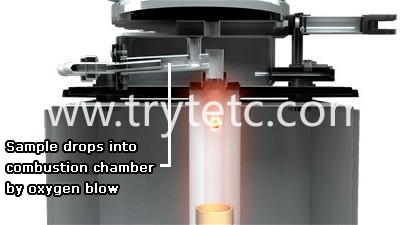

Samples for elemental analyzers are packed by tin-foil cups/capsules, the combustion residues will be remained in the combustion crucible and need to be replaced approximate every 350 tests. Currently manual combustion crucible replacing is required by competitorŌĆÖs elemental analyzerswhich will lead to the following inevitable problems:

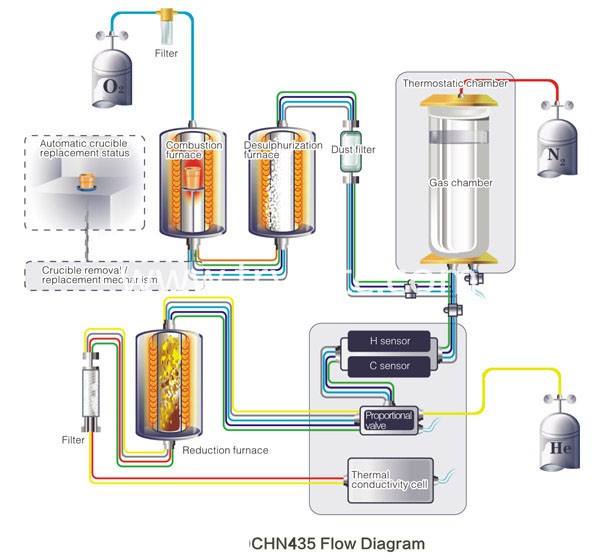

SDCHN435’╝Ü

Automatic Combustion Crucible Replacing’╝łPatent No.: ZL200710303473.9’╝ē

No Disassembling, No Cooling, No waiting

Finish the crucible replacing by one click.

Applicaton:

Tryte Carbon Hydrogen & Nitrogen Analyzer can be used to determine the carbon, hydrogen and nitrogen content in coal, coke, food, soil, fertilizer, etcin the fields of power plant, coal mine, metallurgy, steel factory and so on.

Conformance of Standards:

ISO29541 Solid mineral fuels ŌĆō Determination of total carbon, hydrogen and nitrogen contentŌĆō Instrumental method

ASTM D5373-08 Standard Test Method for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Laboratory Samples of Coal and Coke

GB/T476-2008 Standard Test method for Determination of Carbon and Hydrogen of Coal

Specifications:

Method: Carbon & Hydrogen: Infrared Absorption

Nitrogen: Thermal Conductivity Detection

Measuring range: Carbon’╝ł0.02%~100%’╝ē Hydrogen’╝ł0.02%~50%’╝ēNitrogen’╝ł0.01%~50%’╝ē

Autoloader’╝Ü34 Samples

Analysis time’╝ÜŌēż5min/per sample

Sample weight: 75~105mg’╝ł100mg recommended’╝ē

Repeatability’╝ÜCadŌēż0.5% HadŌēż0.15% Nad Ōēż 0.08%

Combustion-supporting gas: Oxygen Purity: Ōēź99.5% Gas Pressure: Ōēź1MPa

Driving gas: Nitrogen/ Dried Compressed Air Gas Pressure: Ōēź1MPa

Carrier gas (TR-CHN435 only)’╝ÜHelium Purity’╝ÜŌēź99.99%, Gas Pressure: Ōēź1MPa

Power requirement’╝Ü220 V’╝ł-15%-10%’╝ē’╝ī50/60Hz

Max. Power: TR-CHN435’╝Ü4.5kW

TR-CH425 /TR-H425/TR-CH415 /TR-H415’╝Ü3.5Kw

Combustion Crucible replacing: Automatic (TR-CHN435, TR-CH425, TR-H425)

Manual (TR-CH415, TR-H415)